Best quality Pu Binder For Mould Processing Product - Doncool 103 CP/IP base blend polyols – INOV

Best quality Pu Binder For Mould Processing Product - Doncool 103 CP/IP base blend polyols – INOV Detail:

Doncool 103 CP/IP base blend polyols

INTRODUCTION

Doncool 103 is blend polyols uses CP or CP/IP as blowing agent, which applies to refrigerators, freezers, and other insulation products. The characteristics of the products are as follows

1. Excellent flow ability, the density of the foam is well-distributed, and the thermal conductivity is low

2. Excellent low-temperature dimensional stability and good cohesiveness;

3. Demoulding time is 6-8 minutes.

PHYSICAL PROPERTY

| Appearance |

Pale yellow transparent liquid |

| Hydroxyl value mgKOH/g |

360-420 |

| Dynamic viscosity(25℃) mPa.S |

3000-4000 |

| Specific gravity (20℃) g/ml |

1.06-1.08 |

| Storage temperature ℃ |

10-25 |

| Pot life Month |

6 |

RECOMMENDED RATIO

|

|

pbw |

|

Doncool 102 |

100 |

| CP or CP/IP |

12-14 |

| Isocyanate |

136-142 |

TECHNOLOGY AND REACTIVITY (the actual value varied as per process conditions)

|

|

Manual mixing |

High pressure machine |

| Material Temperature ℃ |

20-25 |

20-25 |

| Mould Temperature ℃ |

35-40 |

35-40 |

| Cream time s |

12-16 |

8-12 |

| Gel time s |

75-85 |

50-70 |

| Tack free time s |

100-120 |

70-100 |

| Free density kg/m3 |

25-26 |

24-25 |

FOAM PERFORMANCES

| Mold density | GB/T 6343 | ≥35kg/m3 |

| Closed-cell rate | GB/T 10799 |

≥90% |

| Thermal conductivity (15℃) | GB/T 3399 | ≤22 mW/(m.K) |

| Compression strength | GB/T8813 | ≥150kPa |

| Dimensional stability 24h -20℃ | GB/T8811 |

≤0.5% |

|

24h 100℃ |

≤1.0% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

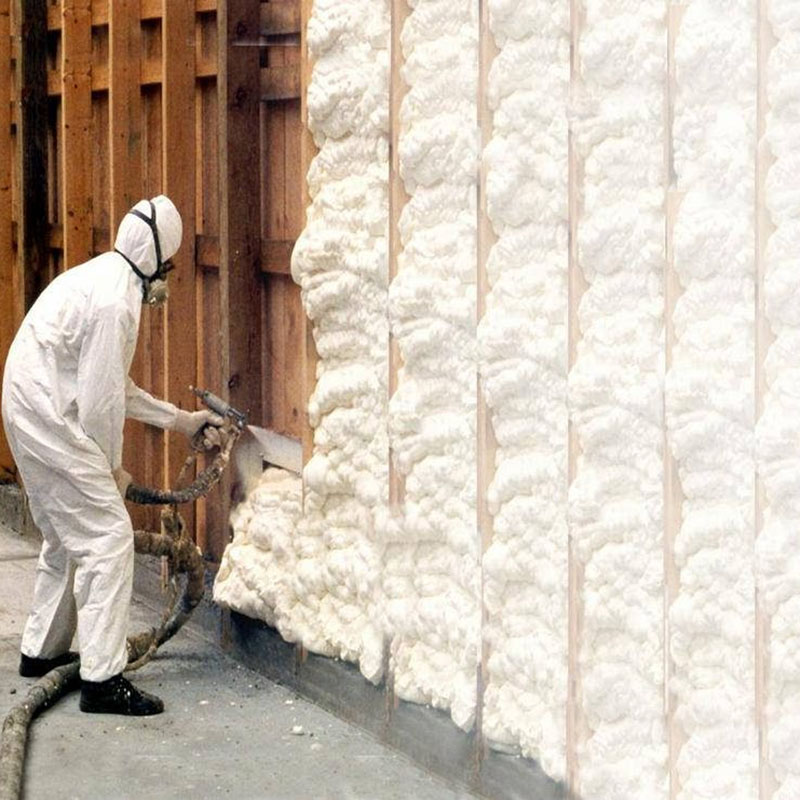

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Best quality Pu Binder For Mould Processing Product - Doncool 103 CP/IP base blend polyols – INOV , The product will supply to all over the world, such as: India, Naples, New York, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.