Best quality Pu Binder For Mould Processing Product - Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam – INOV

Best quality Pu Binder For Mould Processing Product - Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam – INOV Detail:

Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam

INTRODUCTION

Donfoam825 blend polyether polyol used in the manufacture of high flame retardant PIR block foam with HFC-365mfc/227 as foaming agent, products and isocyanate reaction by the formation of the foam has uniform foam cell , low thermal conductivity, thermal insulation performance is good, flame retardant performance is good, low temperature no shrinking crack etc. Widely used in the process of all kinds of insulation work such as: building external wall, cold storage, tanks, large pipes etc.

PHYSICAL PROPERTY

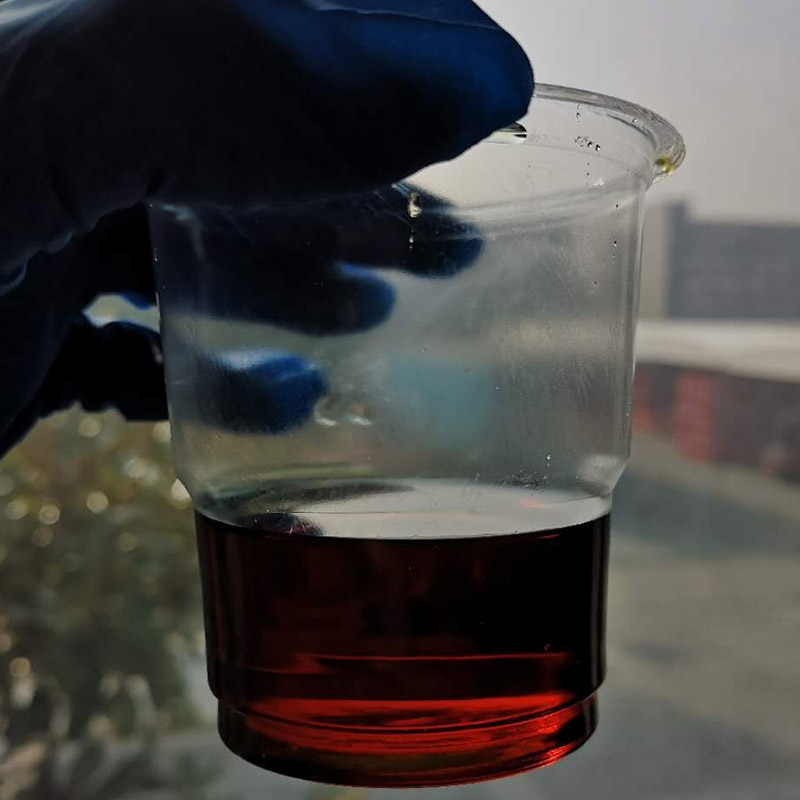

| Appearance |

Light yellow to brown transparent liquid |

| Dynamic viscosity(25℃) mPa.S |

300±100 |

| Density (20℃) g/ml |

1.20±0.1 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

RECOMMENDED RATIO

| Raw materials |

pbw |

| DK-1101 Blend Polyether Polyol |

100 |

| Isocyanate |

180±20 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High pressure machine |

| Raw material temperature ℃ |

20-25 |

20-25 |

| Mould temperature ℃ |

50-60 |

50-60 |

| Cream time s |

25-35 |

20-30 |

| Gel time s |

90.-130 |

70-100 |

| Tack free time s |

150-200 |

120-160 |

| Free density kg/m3 |

28-30 |

27-29 |

MACHINERY FOAM PERFORMANCES

| Overall Mold density | GB 6343 |

≥45kg/m3 |

| Molding Core Density |

≥40kg/m3 |

|

| Closed-cell Rate | GB 10799 | ≥90% |

| Initial Thermal Conductivity(15℃) | GB 3399 |

≤24mW/(m.K) |

| Compressive Strength | GB/T8813 |

≥150kPa |

| Dimentional Stability 24h -20℃

24h 70℃ |

GB/T8811 |

≤1% ≤1.5% |

| Water Absorption Rate | GB 8810 |

≤3% |

| Flammability | GB 8624 |

B1/B2/B3 |

| Closed-cell Rate | GB 10799 |

≥90% |

| Initial Thermal Conductivity(15℃) | GB 3399 |

≤24mW/(m.K) |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Best quality Pu Binder For Mould Processing Product - Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam – INOV , The product will supply to all over the world, such as: Roman, Mexico, Vietnam, We have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.