Best quality Pu Binder For Mould Processing Product - Donpanel 415PIR HFC-365mfc base blend polyols for PIR – INOV

Best quality Pu Binder For Mould Processing Product - Donpanel 415PIR HFC-365mfc base blend polyols for PIR – INOV Detail:

Donpanel 422 HCFC-141b base blend polyols for continuous PUR

INTRODUCTION

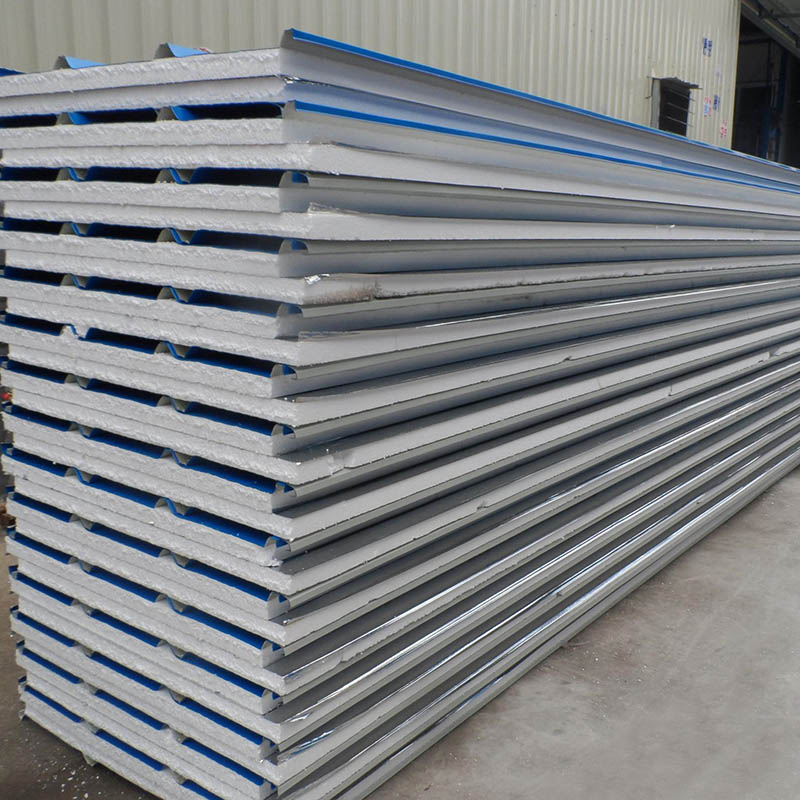

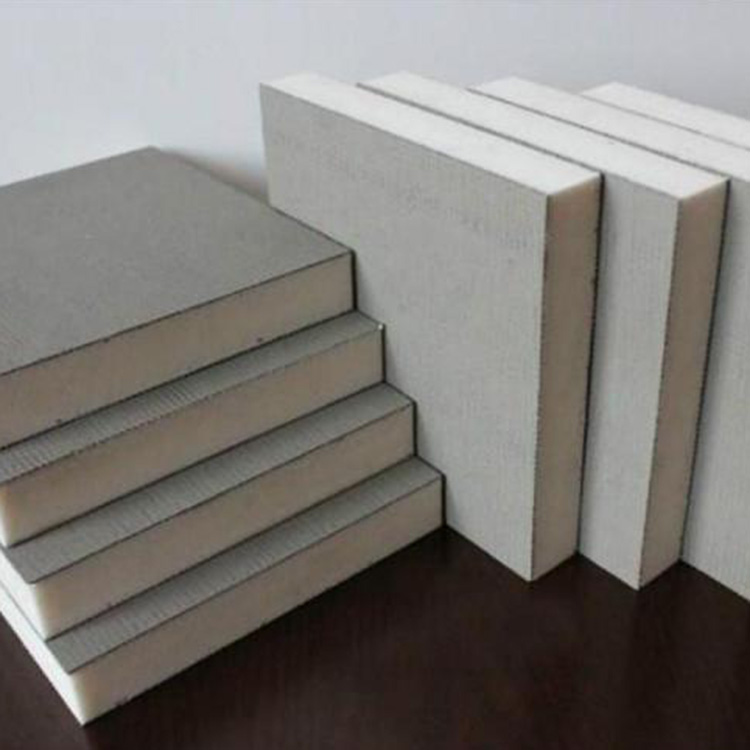

DonPanel 415/PIR is a compound which consists of polyols, surfactants, catalysts, and flame retardant , mixture of HFC-245fa as blowing agent in a special ratio. The foam has good thermal insulation property, light weight, high compression strength and flame retardant and other advantages. It is widely used to produce sandwich plates, corrugated panels etc, which applies to make cold stores, cabinets, portable shelters etc.

PHYSICAL PROPERTY

|

DonPanel 415/PIR |

ISO |

|

|

Appearance |

Light yellow to brown liquid |

Brown liquid |

|

Hydroxyl value mgKOH/g |

200-300 |

N/A |

|

Dynamic viscosity (25℃) mPa.S |

300-500 |

200-250 |

|

Specific gravity (20℃) g/ml |

1.10-1.16 |

1.20-1.25 |

|

Storage temperature ℃ |

10-25 |

10-25 |

|

Storage stability month |

6 |

12 |

RECOMMENDED RATIO

|

Raw materials |

PBW |

|

DonPanel 415/PIR |

100 |

|

Isocyanate |

130-150 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High Pressure Injection machine |

|

Raw material temperature ℃ |

20-25 |

20-25 |

|

Moulding temperature ℃ |

35-45 |

35-45 |

|

Cream time s |

30-50 |

20-30 |

|

Gel time s |

120-200 |

70-150 |

|

Free density kg/m3 |

28-31 |

27-30 |

FOAM PERFORMANCES

|

Moulding density |

ASTM D 1622-08 |

≥45kg/m3 |

|

Closed cell content |

ASTM D 2856 |

≥90% |

|

Thermal conductivity(23℃) |

ASTM C 518-10 |

≤24mW/(m.K) |

|

Compression strength |

ASTM D 1621-10 |

≥140kPa |

|

Dimensional stability 24h -20℃ 24h 100℃ |

ASTM D 2126-09 |

≤1% ≤1.5% |

|

Flammability |

DIN4102 |

B2 |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Best quality Pu Binder For Mould Processing Product - Donpanel 415PIR HFC-365mfc base blend polyols for PIR – INOV , The product will supply to all over the world, such as: Paris, Hanover, Accra, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly