Fast delivery Three Component Mdi Polyurethane System Mdi - Donpanel 415PIR HFC-365mfc base blend polyols for PIR – INOV

Fast delivery Three Component Mdi Polyurethane System Mdi - Donpanel 415PIR HFC-365mfc base blend polyols for PIR – INOV Detail:

Donpanel 422 HCFC-141b base blend polyols for continuous PUR

INTRODUCTION

DonPanel 415/PIR is a compound which consists of polyols, surfactants, catalysts, and flame retardant , mixture of HFC-245fa as blowing agent in a special ratio. The foam has good thermal insulation property, light weight, high compression strength and flame retardant and other advantages. It is widely used to produce sandwich plates, corrugated panels etc, which applies to make cold stores, cabinets, portable shelters etc.

PHYSICAL PROPERTY

|

DonPanel 415/PIR |

ISO |

|

|

Appearance |

Light yellow to brown liquid |

Brown liquid |

|

Hydroxyl value mgKOH/g |

200-300 |

N/A |

|

Dynamic viscosity (25℃) mPa.S |

300-500 |

200-250 |

|

Specific gravity (20℃) g/ml |

1.10-1.16 |

1.20-1.25 |

|

Storage temperature ℃ |

10-25 |

10-25 |

|

Storage stability month |

6 |

12 |

RECOMMENDED RATIO

|

Raw materials |

PBW |

|

DonPanel 415/PIR |

100 |

|

Isocyanate |

130-150 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High Pressure Injection machine |

|

Raw material temperature ℃ |

20-25 |

20-25 |

|

Moulding temperature ℃ |

35-45 |

35-45 |

|

Cream time s |

30-50 |

20-30 |

|

Gel time s |

120-200 |

70-150 |

|

Free density kg/m3 |

28-31 |

27-30 |

FOAM PERFORMANCES

|

Moulding density |

ASTM D 1622-08 |

≥45kg/m3 |

|

Closed cell content |

ASTM D 2856 |

≥90% |

|

Thermal conductivity(23℃) |

ASTM C 518-10 |

≤24mW/(m.K) |

|

Compression strength |

ASTM D 1621-10 |

≥140kPa |

|

Dimensional stability 24h -20℃ 24h 100℃ |

ASTM D 2126-09 |

≤1% ≤1.5% |

|

Flammability |

DIN4102 |

B2 |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

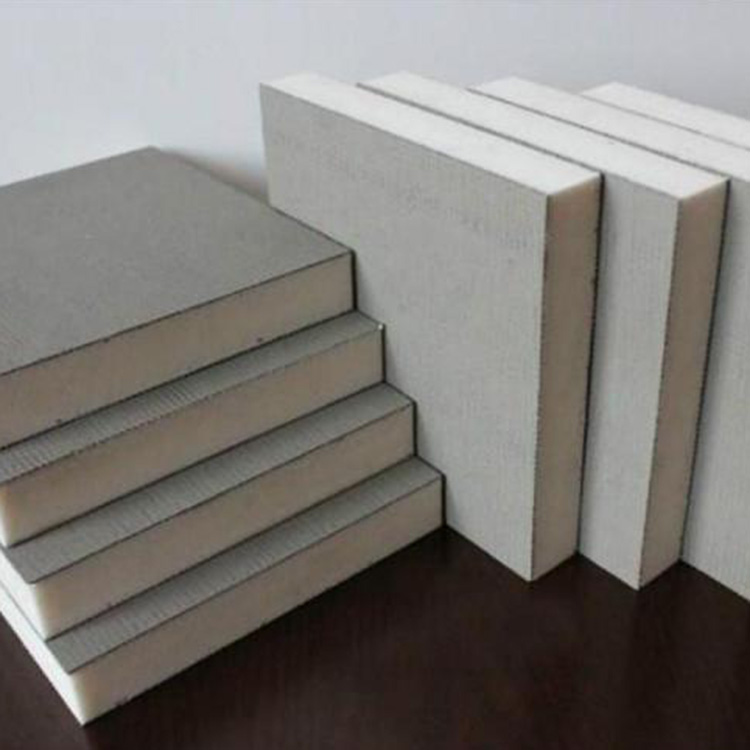

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Fast delivery Three Component Mdi Polyurethane System Mdi - Donpanel 415PIR HFC-365mfc base blend polyols for PIR – INOV , The product will supply to all over the world, such as: Istanbul, Puerto Rico, Peru, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!