High Quality Memory Foam - Pu Shoe Upper Resin – INOV

High Quality Memory Foam - Pu Shoe Upper Resin – INOV Detail:

Pu Shoe Upper Resin

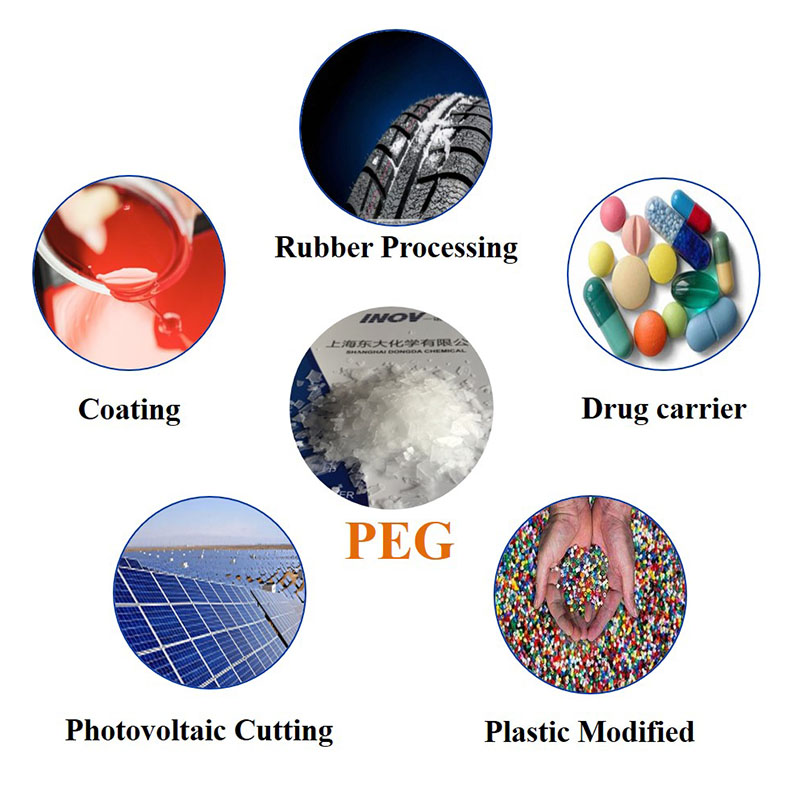

COMPOSITION

This system is consist of four components, polyol, ISO, curing agent and catalyst.

CHARACTERISTICS

Mixing Temperature 30~40℃, Curing Temperature 80~90℃, Demould time 8~10 min (adjustable), the Hardness of finished product could be adjusted by changing the materials ratio of component A+C/B.

STORAGE

Store in a cool and dry place. If you can’t use one drum up at one time, please fill Nitrogen gas and seal the drum well. The shelf life of original packing is 6 months.

PHYSICAL PROPERTIES

|

Reaction parameters |

|||||

|

Finished Product Hardness / Shore A |

70 |

74 |

79 |

82 |

|

| Mass ratio |

DX3520-B |

62 |

68 |

75 |

80 |

|

DX3580-A |

97 |

96 |

95 |

94 |

|

|

DX3580-C |

3 |

4 |

5 |

6 |

|

|

Catalyst / DX3580-A(%) |

0.29 |

0.27 |

0.25 |

0.25 |

|

|

Defoaming agent / DX3580-A(%) |

0.45 |

0.47 |

0.49 |

0.53 |

|

|

Gel time / min |

3 |

3 |

3 |

3 |

|

|

Mechanical Properties of finished product |

||||

|

Hardness / Shore A |

70 |

74 |

79 |

82 |

|

Tensile strength / MPa |

35 |

44 |

47 |

49 |

|

100% Modulus / MPa |

2.2 |

2.8 |

3.9 |

5.4 |

|

300% Modulus / MPa |

4.6 |

6.5 |

8.5 |

9.8 |

|

Ultimate Elongation / % |

540 |

520 |

500 |

490 |

|

Tear Strength ( without Nick ) / (KN/m) |

56 |

66 |

76 |

89 |

|

Tear Strength ( with Nick ) / (KN/m) |

12 |

17 |

22 |

35 |

Product detail pictures:

Related Product Guide:

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for High Quality Memory Foam - Pu Shoe Upper Resin – INOV , The product will supply to all over the world, such as: New Delhi, Rome, panama, We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,