High Quality Polyurethane Rigid Foam System - Donpipe 301 water base blend polyols for pipeline insulation – INOV

High Quality Polyurethane Rigid Foam System - Donpipe 301 water base blend polyols for pipeline insulation – INOV Detail:

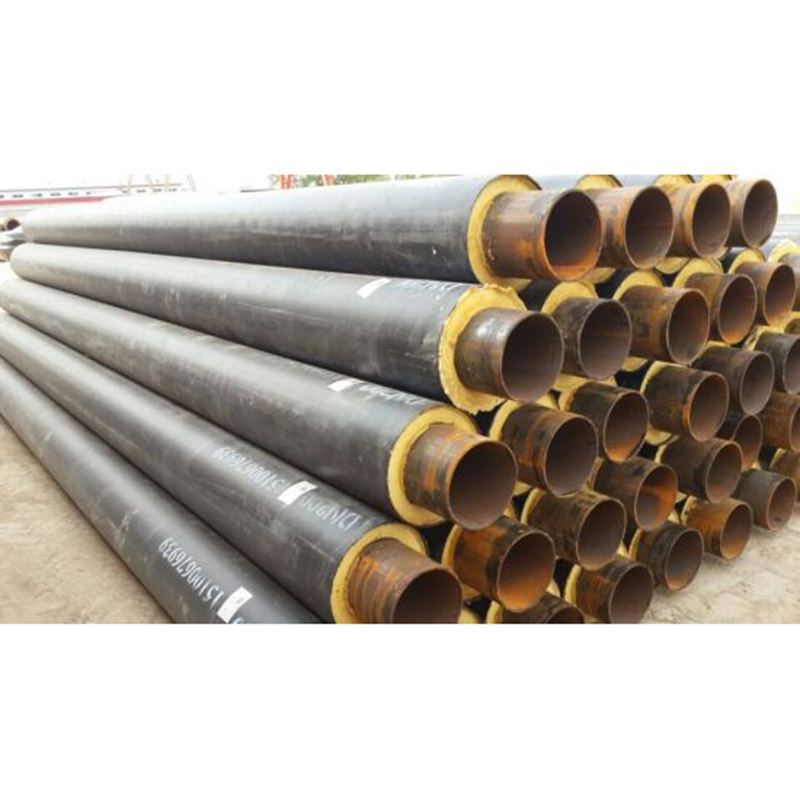

Donpipe 301 water base blend polyols for pipeline insulation

INTRODUCTION

This product is a type of blend polyols with water as foaming agent, which is specially researched for rigid PUF to produce thermal insulation pipes. It is widely used in steam pipes, liquefied nature gas running pipes, oil pipes and other fields. The characteristics are as follows:

(1) good flowability, by regulating formula to suit different pipe diameters.

(2) high temperature-resistance performance, long standing in 150℃

(3) excellent low temperature dimensional stability

PHYSICAL PROPERTY

| Appearance |

Light yellow to brown transparent liquid |

| Hydroxyl value mgKOH/g |

250-450 |

| Dynamic viscosity(25℃) mPa.S |

300-600 |

| Density (20℃) g/ml |

1.10-1.16 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

TECHNOLOGY AND REACTIVITY (Component temperature is 20℃, the actual value is varied according to pipe diameter and processing condition.)

|

|

Manual mixing |

High pressure machine |

| Ratio(POL/ISO) |

1:1.40-1.1.60 |

1:1.40-1.60 |

| Rise time s |

20-40 |

15-35 |

| Gel time s |

80-200 |

80-160 |

| Tack free time s |

≥150 |

≥150 |

| Free density kg/m3 |

34.0-36.0 |

33.0-35.0 |

FOAM PERFORMANCES

| Mold density | GB 6343 | 60-80kg/m3 |

| Closed-cell rate | GB 10799 |

≥90% |

| Thermal conductivity (15℃) | GB 3399 |

≤33mW/(m.K) |

| Compression strength | GB/T8813 | ≥250kPa |

| Water absorption | GB 8810 |

≤3(V/V)% |

| Dimensional stability 24h -30℃ | GB/T8811 |

≤1.0% |

|

24h 100℃ |

≤1.5% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for High Quality Polyurethane Rigid Foam System - Donpipe 301 water base blend polyols for pipeline insulation – INOV , The product will supply to all over the world, such as: Sacramento, UAE, Sacramento, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!