Manufacturer for Pouring Pu Material - PCL Prepolymer – INOV

Manufacturer for Pouring Pu Material - PCL Prepolymer – INOV Detail:

High hardness two component system

DESCRIPTION

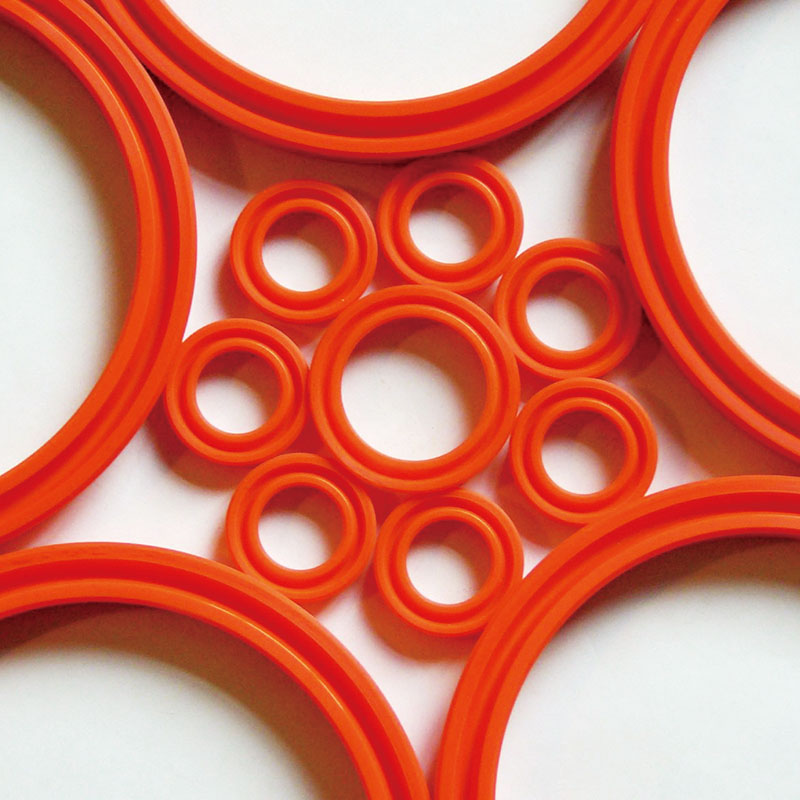

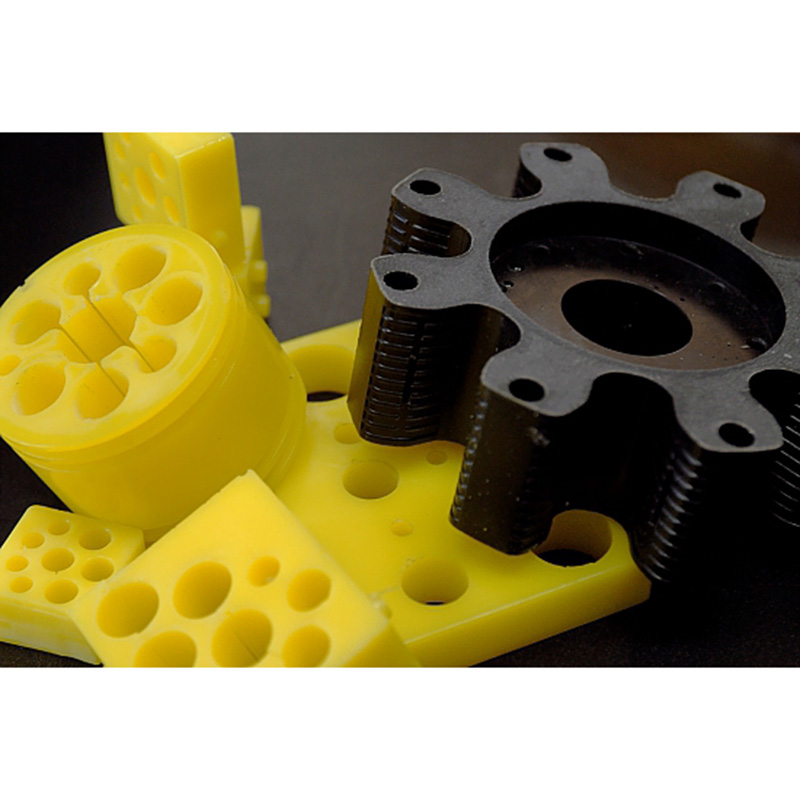

It’s used to make rods, caster wheels, rollers, Sealing rings, sieve plates. It is specially used for some high performance Pu products.

Characteristic: Excellent abrasion resistance, Nice mechanical properties, High temperature resistance, Acid resistance, color can be regulated by adding pigment.

SPECIFICATION

|

Type |

D4136 |

D4336 |

D4155 |

D4160 |

D4190 |

D4590 |

|

NCO content /% |

3.3±0.1 |

3.6±0.2 |

5.5±0.2 |

6.0±0.2 |

9.0±0.2 |

9.0±0.2 |

|

Appearance at 20 ℃ |

White solid |

|||||

|

Curing agent 100g PU Prepolymer/g |

MOCA 9.7 |

MOCA 10.5 |

MOCA 16 |

MOCA 17.5 |

MOCA 25.5 |

BDO 9 |

|

Mixing temperature /℃(PU Prepolymer) |

90/120 |

90/120 |

75/110 |

80/120 |

70/110 |

80/40 |

|

Gel time /min |

8 |

8 |

5 |

4.5 |

2 |

5 |

|

Hardness (Shore A) |

60±1 |

82±1 |

91±1 |

94±1 |

75D |

93±2 |

AUTOMATIC CONTROL

The production is controlled by DCS system, and packing by automatic filling machine. Package is 200KG/DRUM Or 20KG/DRUM.

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Manufacturer for Pouring Pu Material - PCL Prepolymer – INOV , The product will supply to all over the world, such as: Doha, Bhutan, Bangalore, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!