Manufacturer for Pu Binder For Bonding Scrap Foam - Donfoam 602 HCFC-141b base blend polyols – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Donfoam 602 HCFC-141b base blend polyols – INOV Detail:

Donfoam 603 ECOMATE base blend polyols

INTRODUCTION

“Wood Imitation” structure foam , is a new type of carving synthetic materials,Donfoam 603 use ECOMATE as blowing agent . It has high mechanical strength and hardness, simple molding process , high production efficiency and excellent appearance.

Characteristics are as follows,

1. excellent repetition molding property. It not only can mould certain shape size, but also mould lifelike wood texture and other designs, good touch

2. appearance and feel close to wood , which could be planed, nailed, drilled, and carved patterns or designs .

3. Mold can be aluminum or steel, and silicon rubber, epoxy resin or other resins, which are low cost and easy machining.

4. process is simple, fast, high efficiency of qualified.

5. physical and mechanical properties is one of optimal synthesis wood produced by various polymer . Physical property can be controlled by adjusting the formula.

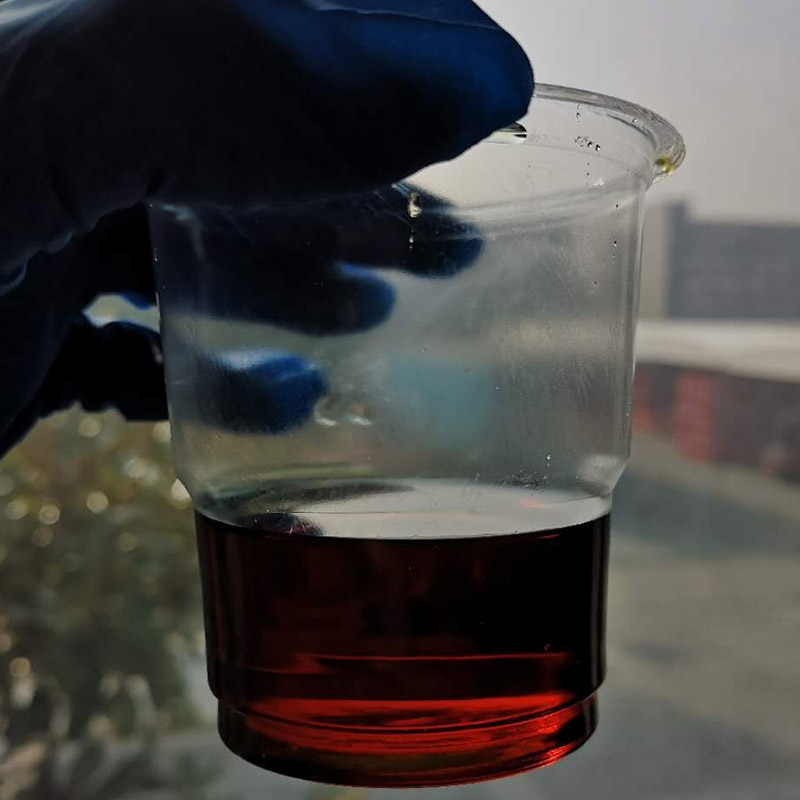

PHYSICAL PROPERTY

|

Appearance Hydroxyl value mgKOH/g Viscosity 25℃ mPa.s Density 20 ℃ g/ml Storage temperature Storage stability Month |

Light yellow to brown yellow viscous liquid 250-400 800-1500 1.10±0.02 10-25 6 |

RECOMMENDED RATIO

|

|

pbw |

|

DFM-103 polyols Isocyanate |

100 100-105 |

Reactivity Characteristics (Actual value varies as per processing conditions)

|

Rise time s Gel time s Tack free time s Free density kg/m3 |

50-70 140-160 200-220 60-300 |

FOAM PERFORMANCES

|

Moulding density Curving strength Compressive strength Tensile strength Surface strength shrinking ratio |

Kg/m3 MPa MPa MPa Shore D % |

100-400 7-10 5-7 5 35-70 ≤0.3 |

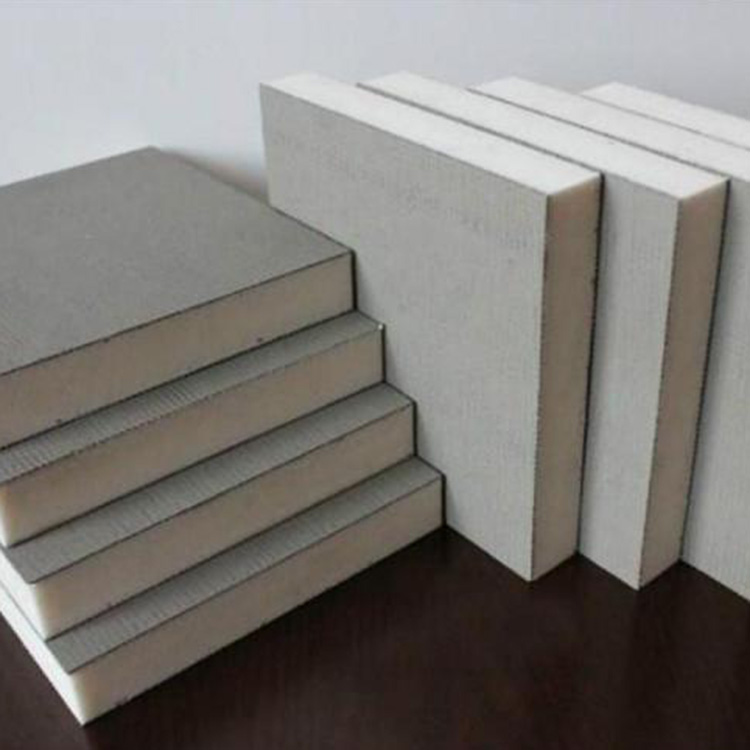

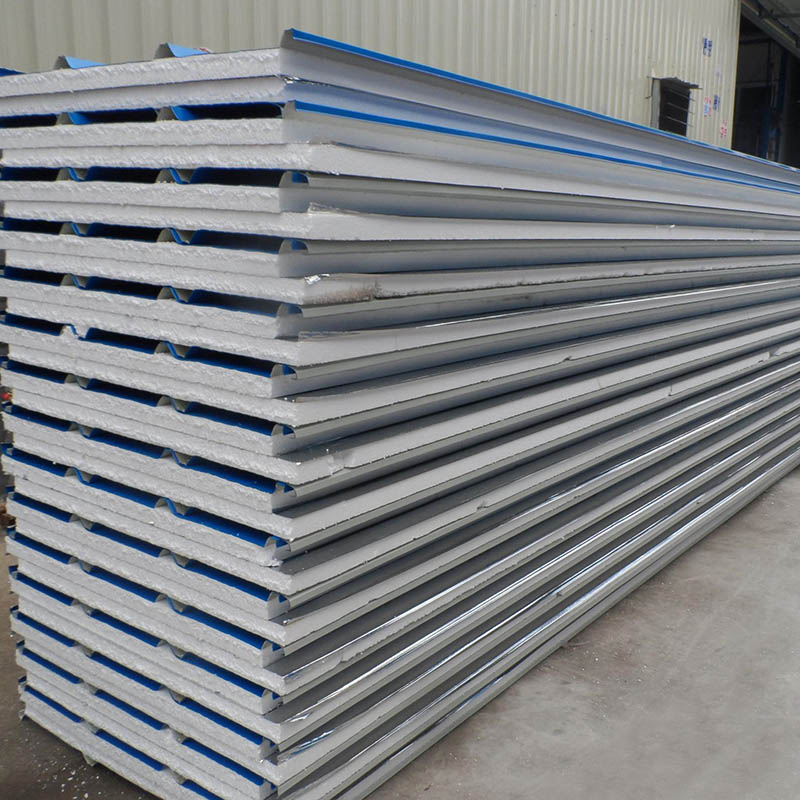

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Manufacturer for Pu Binder For Bonding Scrap Foam - Donfoam 602 HCFC-141b base blend polyols – INOV , The product will supply to all over the world, such as: Uganda, Japan, Bolivia, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!