Manufacturer for Pu Binder For Bonding Scrap Foam - Donpanel 422 HCFC-141b base blend polyols for continuous PUR – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Donpanel 422 HCFC-141b base blend polyols for continuous PUR – INOV Detail:

Donpanel 422 HCFC-141b base blend polyols for continuous PUR

INTRODUCTION

DonPanel 422/ PUR blend polyols is a compound which consists of polyether polyols, surfactants, catalysts, HCFC-141B and flame retardant in a special ratio. The foam has good thermal insulation property, light in weight, high compression strength and flame retardant and other advantages. It is widely used to produce continuous sandwich panels, corrugated panels etc, which applies to make cold stores, cabinets, portable shelters and so on.

PHYSICAL PROPERTY

|

Appearance |

Light yellow transparent viscous liquid |

|

Hydroxyl value mgKOH/g |

300-340 |

|

Dynamic viscosity (25℃) mPa.S |

300-400 |

|

Density (20℃) g/ml |

1.12-1.16 |

|

Storage temperature ℃ |

10-25 |

|

Storage stability month |

6 |

RECOMMENDED RATIO

|

Raw materials |

PBW |

|

DonPanel 422 blend polyols |

100 |

|

Isocyanate |

120-130 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High temperature machine |

|

Raw material temperature ℃ |

20-25 |

20-25 |

|

Mould temperature ℃ |

35-45 |

35-45 |

|

Cream time s |

8-16 |

6-10 |

|

Gel time s |

30-60 |

30-40 |

|

Free density kg/m3 |

28.0-35.0 |

33.0-35.0 |

FOAM PERFORMANCES

|

Mold density |

GB 6343 |

≥40kg/m3 |

|

Closed-cell rate |

GB 10799 |

≥90% |

|

Thermal conductivity(15℃) |

GB 3399 |

≤22mW/(m.K) |

|

Compression strength |

GB/T 8813 |

≥140kPa |

|

Adhesive strength |

GB/T 16777 |

≥120kPa |

|

Dimensional stability 24h -20℃ 24h 100℃ |

GB/T 8811 |

≤1% ≤1.5% |

|

Flame retardant grade |

GB/T8624 |

B2 |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

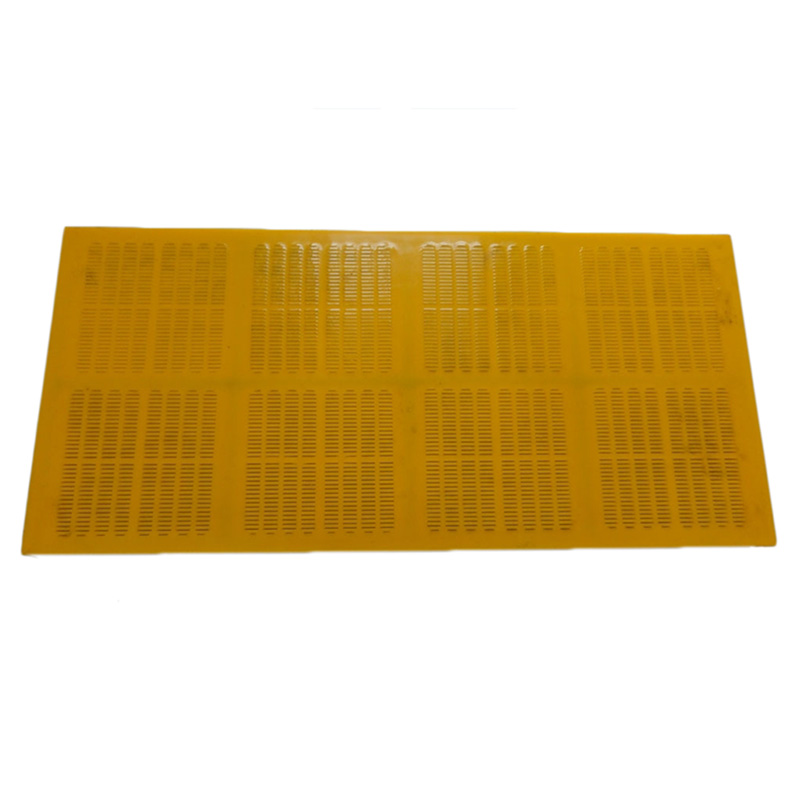

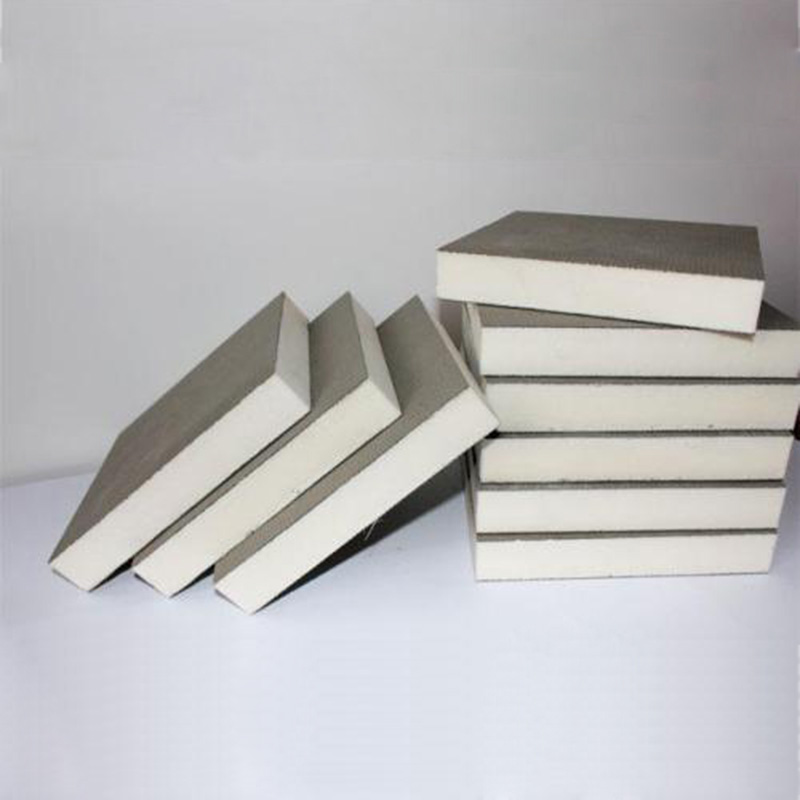

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for Manufacturer for Pu Binder For Bonding Scrap Foam - Donpanel 422 HCFC-141b base blend polyols for continuous PUR – INOV , The product will supply to all over the world, such as: Hungary, Nepal, Guatemala, To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our goods list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're going to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.