Professional China Low Hardness Polyurethane System - Donpanel 423 CP/IP base blend polyols for continuous PIR – INOV

Professional China Low Hardness Polyurethane System - Donpanel 423 CP/IP base blend polyols for continuous PIR – INOV Detail:

Donpanel 423 CP/IP base blend polyols for continuous PIR

INTRODUCTION

DonPanel 423 system is a four components system which consists of blend polyols, polymeric MDI, catalyst and blowing agent (pentane series). The foam has good thermal insulation property, light in weight, high compression strength and flame retardant and other advantages. It is widely used to produce continuous sandwich panels, corrugated panels etc, which applies to make cold stores, cabinets, portable shelters and so on.

PHYSICAL PROPERTY

K1-blend polyols DonPanel 423

| Appearance |

Light yellow to brown transparent liquid |

| OHvalue mgKOH/g |

260-300 |

| Dynamic viscosity(25℃) mPa.S |

1800-2200 |

| Density (20℃) g/ml |

1.10-1.16 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

K2-Polymeric MDI DD-44V80

| Appearance |

brown transparent liquid |

| NCO content % |

30.50 |

| Dynamic viscosity (25℃) mPa.S |

600-700 |

| Density (20℃) g/ml |

1.24 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

12 |

K3-Cat 2816

| Appearance |

Light yellow transparent liquid |

| Dynamic viscosity (25℃) mPa.S |

1200-1600 |

| Density (20℃) g/ml |

0.96 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

RECOMMENDED RATIO

| Raw materials |

pbw |

| DonPanel 423 |

100 g |

| Cat2816 |

1-3 g |

| Pentane (Cyclopentane/Isopentane) |

7-10 g |

| Polymeric MDI DD-44V80 |

135-155 g |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High pressure machine |

| Raw material temperature ℃ |

20-25 |

20-25 |

| Mould temperature ℃ |

45-55 |

45-55 |

| Cream time s |

10-15 |

6-10 |

| Gel time s |

40-60 |

40-60 |

| Free density kg/m3 |

34.0-36.0 |

33.0-35.0 |

MACHINERY FOAM PERFORMANCES

| Mold density | ISO 845 |

≥38kg/m3 |

| Closed-cell rate | ASTM D 2856 |

≥90% |

| Thermal conductivity (15℃) | EN 12667 |

≤24mW/(m.K) |

| Compression strength | EN 826 |

≥120kPa |

| Adhesive strength | GB/T 16777 |

≥100kPa |

| Dimensional stability 24h -30℃ | ISO 2796 |

≤0.5% |

|

24h -100℃ |

≤1.0% |

|

| Flame retardant grade | DIN 4102 |

Level B2 (no burning) |

| Water absorption ratio | GB 8810 |

≤3% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

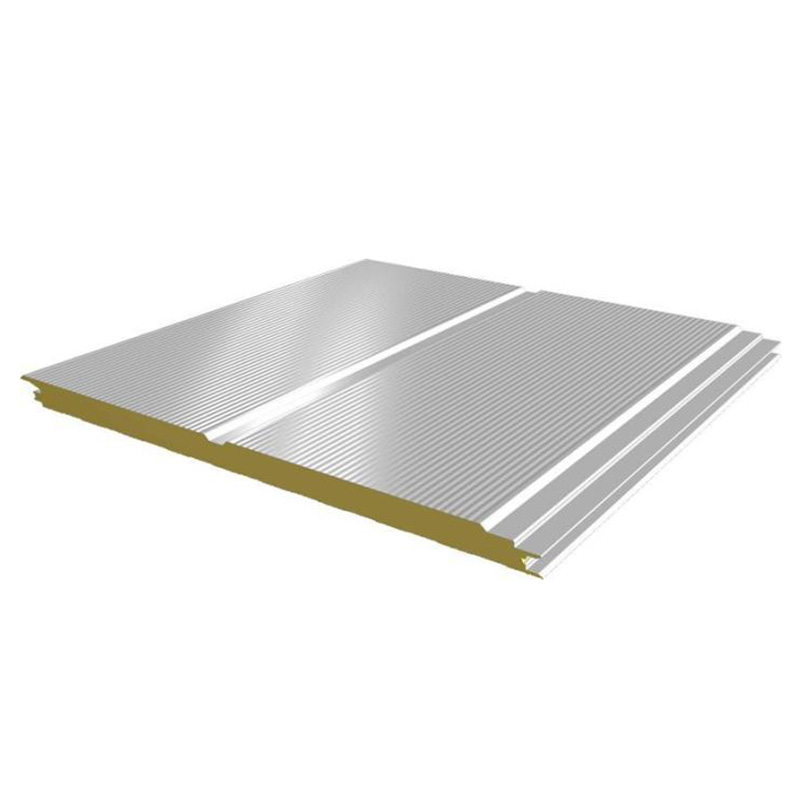

Product detail pictures:

Related Product Guide:

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Professional China Low Hardness Polyurethane System - Donpanel 423 CP/IP base blend polyols for continuous PIR – INOV , The product will supply to all over the world, such as: Tunisia, Denmark, Atlanta, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.