High reputation Castable Polyurethane Shoe Mould Prepolymer - Donpanel 422PIR HCFC-141b base blend polyols for continuous PIR – INOV

High reputation Castable Polyurethane Shoe Mould Prepolymer - Donpanel 422PIR HCFC-141b base blend polyols for continuous PIR – INOV Detail:

Donpanel 423 CP/IP base blend polyols for continuous PIR

INTRODUCTION

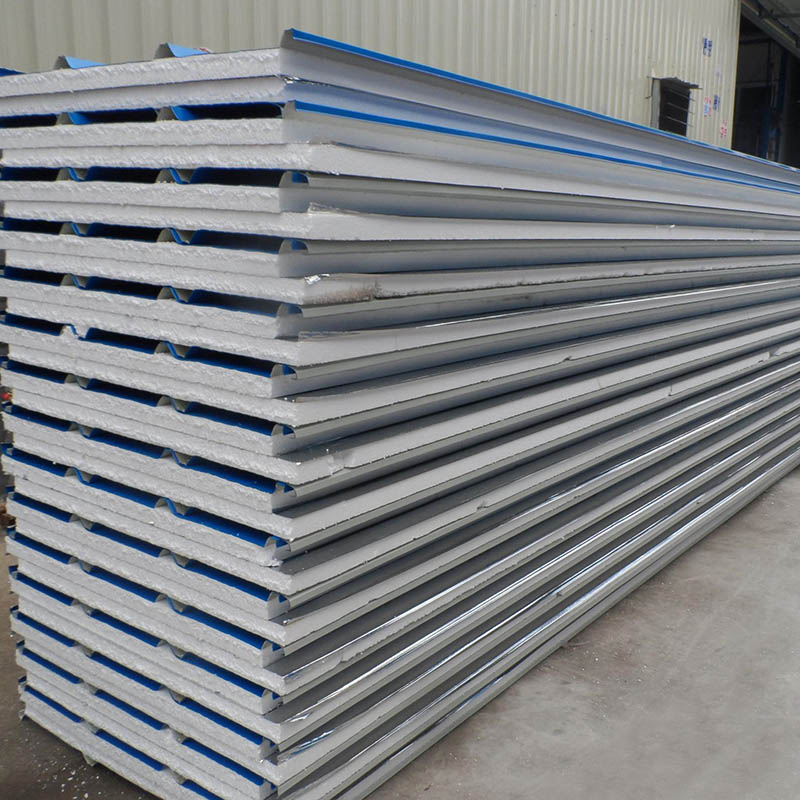

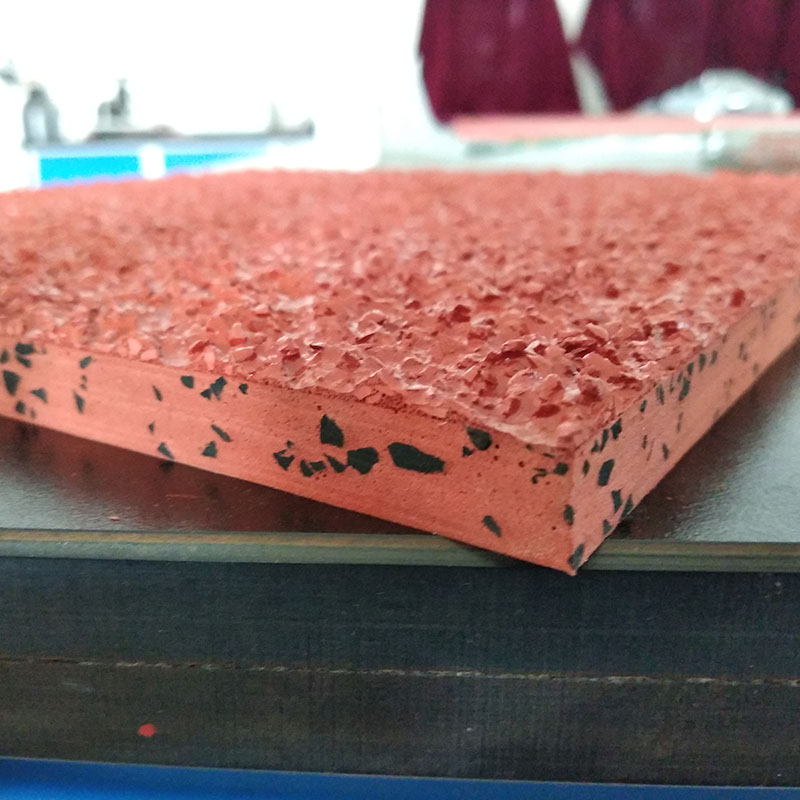

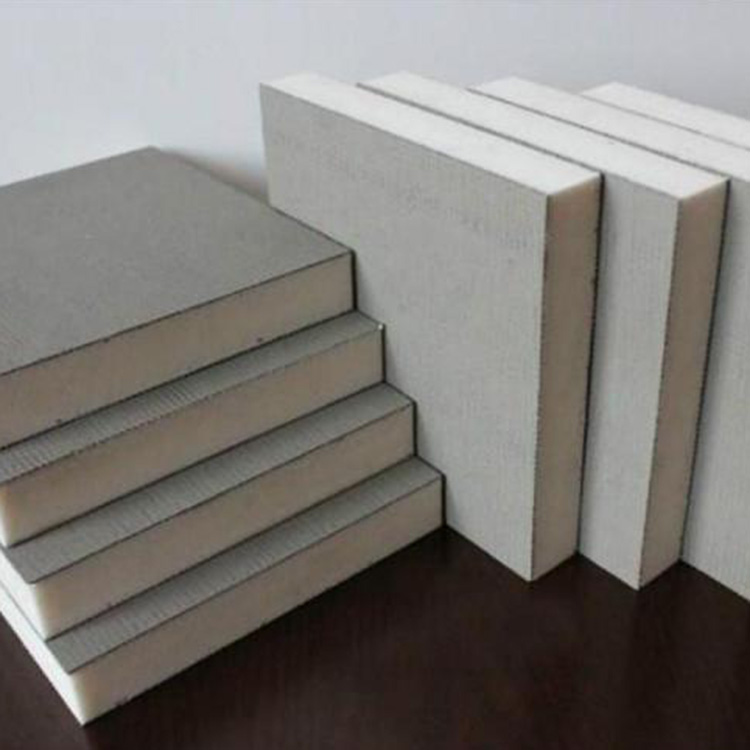

Donpanel 422/PIR blend polyols is a compound which consists of polyether & polyester polyols, surfactants, catalysts and flame retardant in a special ratio. The foam has good thermal insulation property, light in weight, high compression strength and flame retardant and other advantages. It is widely used to produce continuous sandwich panels, corrugated panels etc, which applies to make cold stores, cabinets, portable shelters and so on.

PHYSICAL PROPERTY

| Appearance |

Light yellow transparent viscous liquid |

|

Hydroxyl value mgKOH/g |

260-300 |

|

Dynamic viscosity (25℃) mPa.S |

1000-1400 |

|

Density (20℃) g/ml |

1.10-1.14 |

|

Storage temperature ℃ |

10-25 |

|

Storage stability month |

6 |

RECOMMENDED RATIO

|

Raw materials |

pbw |

|

blend polyols |

100 |

|

Isocyanate |

175-185 |

|

141B |

15-20 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

items |

Manual mixing |

High Pressure Machine |

| Raw material temperature ℃ |

20-25 |

20-25 |

| Moulding temperature ℃ |

45-55 |

45-55 |

| Cream time s |

10-15 |

6~10 |

| Gel time s |

40-50 |

30-40 |

| Free density kg/m3 |

34.0-36.0 |

33.0-35.0 |

MACHINERY FOAM PERFORMANCES

| Moulding density | GB 6343 |

≥45kg/m3 |

| Closed-cell rate | GB 10799 |

≥90% |

| Thermal conductivity(15℃) | GB 3399 |

≤24mW/(m.K) |

|

Compression strength |

GB/T 8813 |

≥200kPa |

| Adhesive strength | GB/T 16777 |

≥120kPa |

| Dimensional stability 24h -20℃ | GB/T 8811 |

≤0.5% |

|

24h 100℃ |

≤1.0% |

|

| Flammability |

GB/T8624 |

Level B2(Cannot Burn) |

| Water absorption ratio |

GB 8810 |

≤3% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

HEALTH AND SAFETY

The Safety and Health information in this data sheet does not contain sufficient detail for safe handling in all cases. For detailed safety and health information refer to the Material Safety Data Sheet for this product.

Emergency calls:INOV Emergency Response Center: No. 307 Shanning Rd, Shanyang Town, Jinshan District, Shanghai, China.

Important legal notice:Sales of the products described herein (“Product”) are subject to the general terms and conditions of sale of INOV Corporation and its affiliates and subsidiaries (collectively, “INOV”). To the knowledge, information and belief of INOV, all the information and recommendations in this publication are accurate as of the date of publication.

WARRANTY

INOV warrants that at the time and place of delivery all Products sold to a buyer of such Products shall conform to the specifications provided by INOV to such buyer of such Products.

DISCLAIMER AND LIMITATION OF LIABILITY

Except as set forth above,INOV makes no other warranty of any kind,express or implied ,including but not limited to any warranty of merchantability or fitness for a particular purpose, noninfringement of any intellectual property right of any third party, or warranties as to quality or correspondence with prior description or sample,and any buyer of products described herein assumes all risk and liability whatsoever resulting from the use of such product, whether used singly or in combination with other substances.

Chemical or other properties purported to be typical of such Products, where stated herein, should be considered as representative of current production and should not be construed to be specifications of any such Products. In all cases, it is the sole responsibility of a buyer to determine the applicability of the information and recommendations contained in this publication and the suitability of any Product for its own particular purpose, and no statements or recommendations made herein are to be construed as a suggestion, recommendation, or authorization to take any action that would infringe any patent or other intellectual property right. A buyer or user of a Product is solely responsible for ensuring that its intended use of such Product does not infringe any third party’s intellectual property rights. INOV’s maximum liability for any claim related to the Products described herein or breach of an agreement associated therewith shall be limited to the purchase price of the Products or portion thereof to which such claim pertains.In no event shall INOV be liable for any consequential,incidental,special or punitive damages,including but not limited to any damages for lost profits or business opportunities or damage to reputation.

WARNING

The behaviour, hazardousness and/or toxicity of the Products referred to in this publication in manufacturing processes and their suitability in any given end-use environment are dependent upon various conditions such as chemical compatibility, temperature, and other variables, which may not be known to INOV. It is the sole responsibility of the buyer or user of such Products to evaluate the manufacturing circumstances and the final Product(s) under actual end-use requirements and to adequately advise and warn future purchasers and users thereof.

Products referred to in this publication may be hazardous and/or toxic and require special precautions in handling. A buyer should obtain Material Safety Data Sheets from INOV containing detailed information on hazardousness and/or toxicity of the products contained herein, together with proper shipping, handling and storage procedures, and should comply with all applicable safety and environmental standards. The Product(s) described herein have not been tested for, and is therefore not recommended or suitable for, uses for which prolonged contact with mucous membranes, abraded skin, or blood is intended or likely, or for uses for which implantation within the human body is intended, and INOV assumes no liability for such uses.

Unless otherwise specified, INOV shall not be liable for or otherwise have any obligation to a buyer of any Products contained in this publication for any technical or other information or advice furnished by INOV in this publication.

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for High reputation Castable Polyurethane Shoe Mould Prepolymer - Donpanel 422PIR HCFC-141b base blend polyols for continuous PIR – INOV , The product will supply to all over the world, such as: Estonia, Bangkok, Houston, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.