Manufacturer for Other Series - Pu Safety Shoe Sole System – INOV

Manufacturer for Other Series - Pu Safety Shoe Sole System – INOV Detail:

Pu Safety Shoe Sole System

INTRODUCTION

PU Safety shoe-sole system is used to make safety shoe outsoles and inner soles. It is polyester-based PU system material, consist of four components, polyol, ISO, hardner and catalyst. The processing of the system is two components. The catalyst, harder, blowing agent and pigment should be mixed thoroughly with the polyol component EXD-3270A, then mix with ISO component EXD-3119B for making final wares.

PHYSICAL PROPERTIES

A, Inner soles of safety shoe-sole preparing method:

|

Items |

EXD-3270A |

EXD-3119B |

|

Ratio(weight ratio) |

100 |

85~88 |

|

Material temperature(℃) |

45~50 |

45~50 |

|

Rise time(s) |

5~7 |

|

|

Tack free time(s) |

30~50 |

|

|

Free foam density (g/cm3) |

0.35~0.4 |

|

|

Mould temperature(℃) |

45~55 |

|

|

Product density(g/cm3) |

0.5~0.55 |

|

|

Hardness(Shore A) |

55~65 |

|

|

Demould time(min) |

3 |

|

|

Elongation at break (%) |

≥550 |

|

|

Tear strength(KN/m) |

≥22 |

|

|

Tensile strength (MPa) |

≥6.0 |

|

|

Ross flexing room temperature |

50,000 times no crack |

|

B, Outsoles of safety shoe-sole preparing method:

|

Items |

EXD-3270A |

EXD-3119B |

|

Ratio(weight ratio) |

100 |

82~85 |

|

Material temperature(℃) |

45~50 |

45~50 |

|

Rise time(s) |

5~7 |

|

|

Tack free time(s) |

30~50 |

|

|

Free foam density (g/cm3) |

0.55~0.6 |

|

|

Mould temperature(℃) |

45~55 |

|

|

Product density(g/cm3) |

0.6~0.8 |

|

|

Hardness(Shore A) |

65~75 |

|

|

Demould time(min) |

3 |

|

|

Elongation at break (%) |

≥600 |

|

|

Tear strength(KN/m) |

≥28 |

|

|

Tensile strength (MPa) |

≥7.3 |

|

|

Ross flexing room temperature |

50,000 times no crack |

|

|

Demould time(min) |

3 |

|

|

Product density(g/cm3) |

0.2~0.3 |

|

|

Hardness(Shore C) |

30~40 |

|

|

Tensile strength(MPa) |

0.45-0.50 |

|

|

Tear strength(KN/m) |

2.50-2.60 |

|

|

Elongation(%) |

280-300 |

|

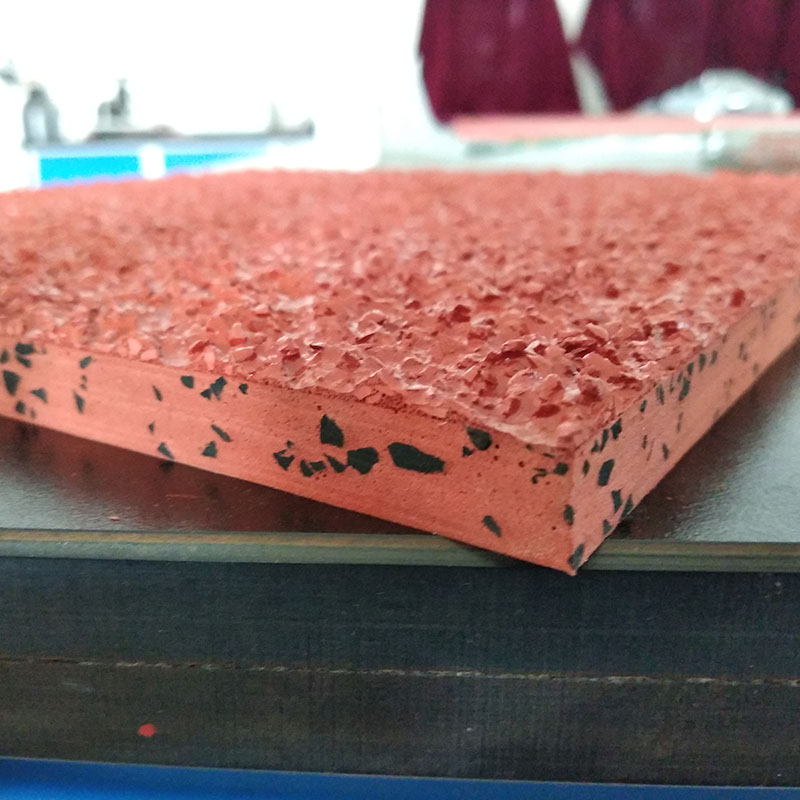

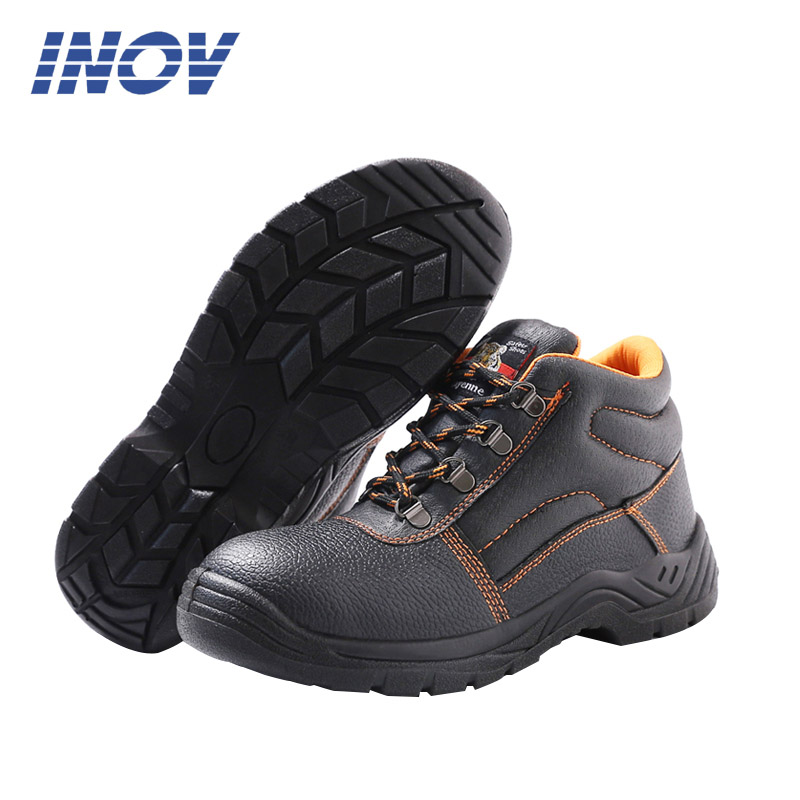

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Manufacturer for Other Series - Pu Safety Shoe Sole System – INOV , The product will supply to all over the world, such as: Guatemala, Peru, Belize, Upon today, we've customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We've been looking forward to doing business with you.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!