Manufacturer for Pouring Pu Material - Quasi MDI-terminated system – INOV

Manufacturer for Pouring Pu Material - Quasi MDI-terminated system – INOV Detail:

Quasi MDI-terminated PTMG system

DESCRIPTION

Component: DY2513 is consist by Components ABC. Component A is polyol, B is polyurethane prepolymer which ended up with isocynate, C is chain extender.

Characteristic: The final product enjoys good anti resistance ability, good rebound. And the hardness can be adjusted by the different ratio. The color can be adjusted by pigment.

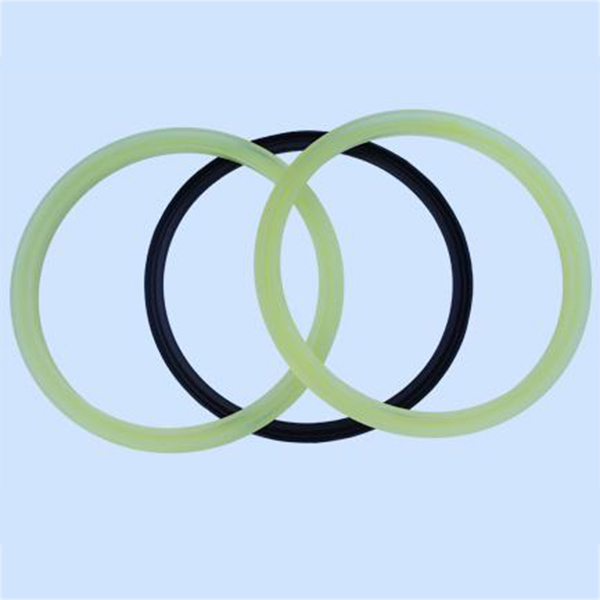

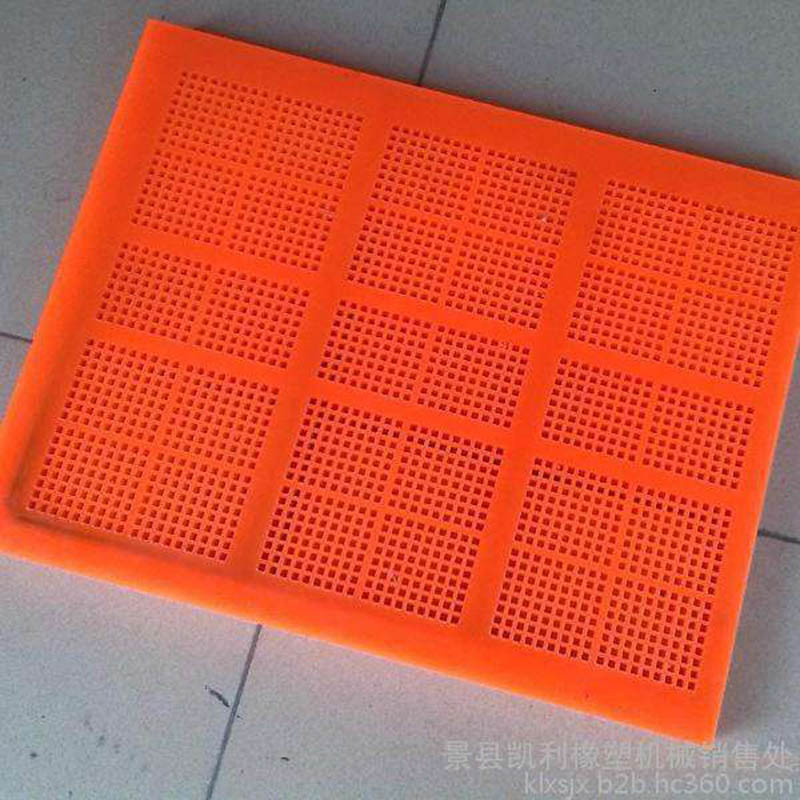

Application: This material was used to produce Polyurethane sieves, PU rollers, cleaning pigs (discs) and other elastomer.

SPECIFICATION

|

Type |

DY2513-B |

DY2513-A |

DY2513-C |

|||||

|

NCO/% |

13.1 |

|

|

|||||

|

Operation temperature /℃ |

45 |

50 |

45 |

|||||

|

Viscosity mPa·s/ |

800 |

1200 |

30 |

|||||

|

Prepolymer |

DY2513-B |

|||||||

|

Chain extender |

DY2513-A﹢DY2513-C |

|||||||

|

Hardness /shore A |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

|

DY2513-B(ratio, by weight ) |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

DY2513-A(ratio, by weight ) |

180 |

150 |

120 |

100 |

80 |

60 |

40 |

20 |

|

DY2513-C(ratio, by wight) |

5.7 |

7 |

8.4 |

9.3 |

10.2 |

11.1 |

12 |

12.9 |

|

Catalyst/total amount A+B+C % |

0.6 |

0.6 |

0.6 |

0.45 |

0.3 |

0.3 |

0.24 |

0.24 |

|

Mold temperature/℃ |

100 |

|||||||

|

Gel time/min |

2,30 |

2,30 |

2,20 |

2,20 |

2,30 |

2,30 |

2,10 |

2,10 |

|

Open Mold Time/ min |

60 |

50 |

40 |

40 |

40 |

40 |

40 |

40 |

Quasi MDI-terminated Polyester system

DESCRIPTION

It is used to produce Polyurethane sieves, PU rollers and other elastomer. It should be processed by mid-temperature casting machine.

The final product enjoys good anti resistance ability, good rebound. And the hardness can be adjusted by the different ratio. The color can be adjusted by pigment.

Application: automotive kits, pipe cleaners, etc., polyurethane large or small product components.

SPECIFICATION

|

Type |

DY3516-B |

DY3516-A |

DY3516-C |

|||||||

|

NCO/% |

16.5±0.2 |

|

|

|||||||

| Operation temperature /℃ |

45 |

70 |

45 |

|||||||

|

Viscosity mPa·s/ |

700 |

730 |

30 |

|||||||

|

Prepolymer |

DY3516-B |

|||||||||

|

Chain extender |

DY3516-A+DY3516-C |

|||||||||

|

Hardness /shore A |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

||

|

DY3516-B(ratio, by weight) |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

||

|

DY3516-A(ratio, by weight) |

380 |

180 |

160 |

130 |

110 |

100 |

80 |

60 |

||

| DY3516-C(ratio, by weight) |

0 |

9.1 |

10 |

11.4 |

12.3 |

12.7 |

13.6 |

14.5 |

||

|

Catalyst/total amount A+B+C % |

0.4 |

0.4 |

0.4 |

0.4 |

0.3 |

0.3 |

0.3 |

0.3 |

||

|

Mold temperature/℃ |

100 |

|||||||||

|

Gel time/min |

5 |

5 |

5 |

5 |

5 |

4 |

4 |

4 |

||

|

Open Mold Time/ min |

50 |

35 |

35 |

30 |

30 |

30 |

30 |

30 |

||

|

Post cure time(90℃)/h |

16 |

|||||||||

AUTOMATIC CONTROL

The production is controlled by DCS system, and packing by automatic filling machine. Package is 200KG/DRUM Or 20KG/DRUM.

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Manufacturer for Pouring Pu Material - Quasi MDI-terminated system – INOV , The product will supply to all over the world, such as: Montreal, Burundi, Hongkong, Due to our dedication, our products are well known throughout the world and our export volume continuously grows every year. We will continue to strive for excellence by providing high quality products that will exceed the expectation of our customers.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!