2019 wholesale price Pipeline Insulation - Quasi MDI-terminated system – INOV

2019 wholesale price Pipeline Insulation - Quasi MDI-terminated system – INOV Detail:

Quasi MDI-terminated PTMG system

DESCRIPTION

Component: DY2513 is consist by Components ABC. Component A is polyol, B is polyurethane prepolymer which ended up with isocynate, C is chain extender.

Characteristic: The final product enjoys good anti resistance ability, good rebound. And the hardness can be adjusted by the different ratio. The color can be adjusted by pigment.

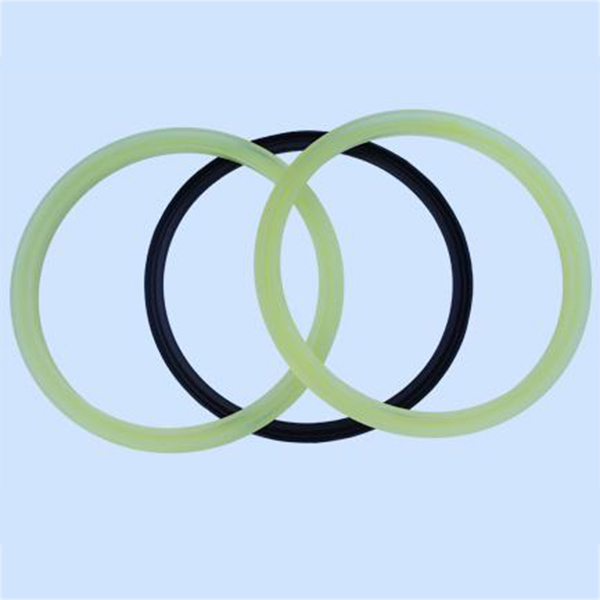

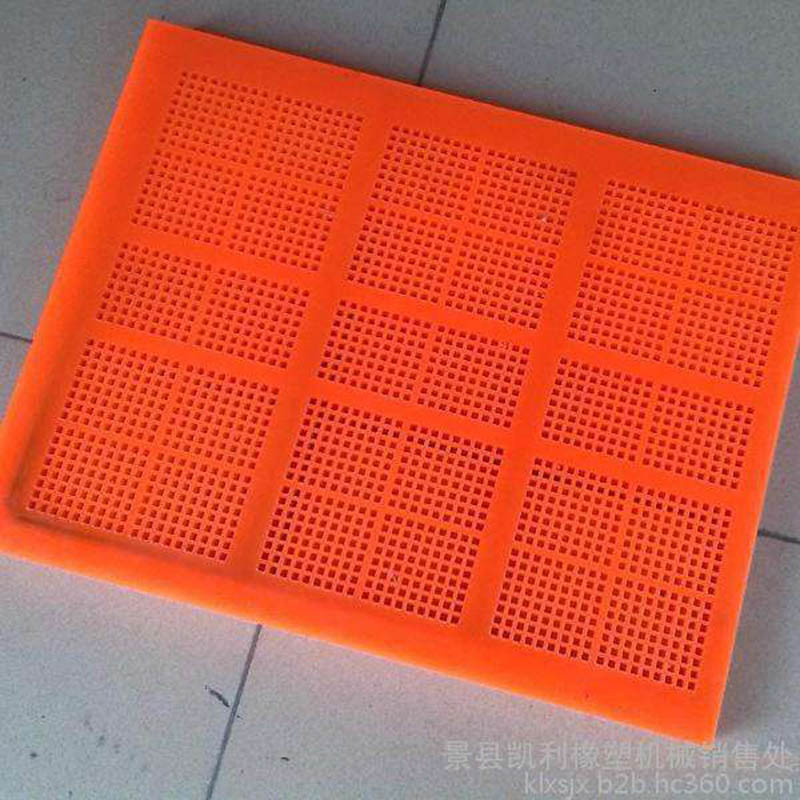

Application: This material was used to produce Polyurethane sieves, PU rollers, cleaning pigs (discs) and other elastomer.

SPECIFICATION

|

Type |

DY2513-B |

DY2513-A |

DY2513-C |

|||||

|

NCO/% |

13.1 |

|

|

|||||

|

Operation temperature /℃ |

45 |

50 |

45 |

|||||

|

Viscosity mPa·s/ |

800 |

1200 |

30 |

|||||

|

Prepolymer |

DY2513-B |

|||||||

|

Chain extender |

DY2513-A﹢DY2513-C |

|||||||

|

Hardness /shore A |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

|

DY2513-B(ratio, by weight ) |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

DY2513-A(ratio, by weight ) |

180 |

150 |

120 |

100 |

80 |

60 |

40 |

20 |

|

DY2513-C(ratio, by wight) |

5.7 |

7 |

8.4 |

9.3 |

10.2 |

11.1 |

12 |

12.9 |

|

Catalyst/total amount A+B+C % |

0.6 |

0.6 |

0.6 |

0.45 |

0.3 |

0.3 |

0.24 |

0.24 |

|

Mold temperature/℃ |

100 |

|||||||

|

Gel time/min |

2,30 |

2,30 |

2,20 |

2,20 |

2,30 |

2,30 |

2,10 |

2,10 |

|

Open Mold Time/ min |

60 |

50 |

40 |

40 |

40 |

40 |

40 |

40 |

Quasi MDI-terminated Polyester system

DESCRIPTION

It is used to produce Polyurethane sieves, PU rollers and other elastomer. It should be processed by mid-temperature casting machine.

The final product enjoys good anti resistance ability, good rebound. And the hardness can be adjusted by the different ratio. The color can be adjusted by pigment.

Application: automotive kits, pipe cleaners, etc., polyurethane large or small product components.

SPECIFICATION

|

Type |

DY3516-B |

DY3516-A |

DY3516-C |

|||||||

|

NCO/% |

16.5±0.2 |

|

|

|||||||

| Operation temperature /℃ |

45 |

70 |

45 |

|||||||

|

Viscosity mPa·s/ |

700 |

730 |

30 |

|||||||

|

Prepolymer |

DY3516-B |

|||||||||

|

Chain extender |

DY3516-A+DY3516-C |

|||||||||

|

Hardness /shore A |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

||

|

DY3516-B(ratio, by weight) |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

||

|

DY3516-A(ratio, by weight) |

380 |

180 |

160 |

130 |

110 |

100 |

80 |

60 |

||

| DY3516-C(ratio, by weight) |

0 |

9.1 |

10 |

11.4 |

12.3 |

12.7 |

13.6 |

14.5 |

||

|

Catalyst/total amount A+B+C % |

0.4 |

0.4 |

0.4 |

0.4 |

0.3 |

0.3 |

0.3 |

0.3 |

||

|

Mold temperature/℃ |

100 |

|||||||||

|

Gel time/min |

5 |

5 |

5 |

5 |

5 |

4 |

4 |

4 |

||

|

Open Mold Time/ min |

50 |

35 |

35 |

30 |

30 |

30 |

30 |

30 |

||

|

Post cure time(90℃)/h |

16 |

|||||||||

AUTOMATIC CONTROL

The production is controlled by DCS system, and packing by automatic filling machine. Package is 200KG/DRUM Or 20KG/DRUM.

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for 2019 wholesale price Pipeline Insulation - Quasi MDI-terminated system – INOV , The product will supply to all over the world, such as: Estonia, Algeria, Mexico, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!